Industrial Asset Tracking & Inventory Management

As the manufacturing industry strives to drive greater efficiency and improve margins, having accurate inventory counts and asset location information becomes paramount. Yet many still rely on outdated paper and spreadsheets, leading to inefficiencies and errors.

At the same time, supply chain disruptions and rising material costs are increasing pressure on companies to optimize spending and asset utilization.

AiRISTA is uniquely positioned to address these challenges with our innovative suite of solutions designed to streamline end-to-end asset tracking and inventory management.

AiRISTA’s Industrial RTLS Technology

At AiRISTA, we’re investing heavily in emerging location data technologies and RTLS infrastructure that will bring down the cost of tags while increasing accuracy. Technologies like Wi-Fi 6 and BLE 5 allow for greater distance and longer tag battery life.

BLE Asset Tags

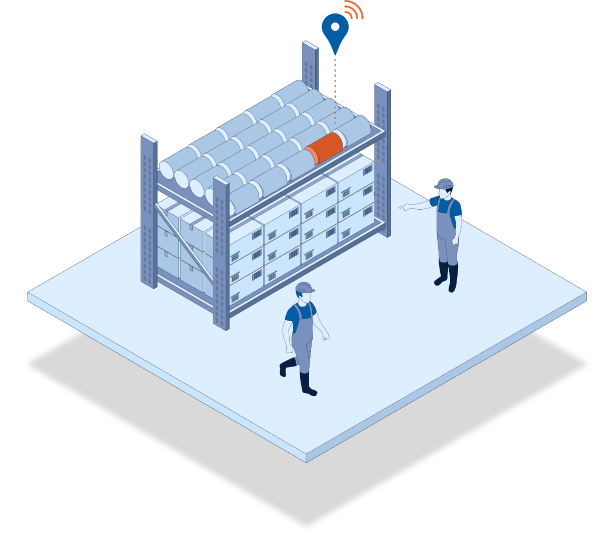

The consumerization of BLE has driven costs to levels where the tag is virtually disposable. And BLE 5.1 allows for sub-meter accuracy and tracking in the vertical dimension. All this makes possible new RTLS use cases for inventory management, enabling manufacturing companies to track thousands of items on vertical shelves in close proximity to each other.

Angle of Arrival (AoA) Gateway

The AoA Gateway looks like an access point and leverages state-of-the-art BLE technology to track assets with sub-meter accuracy both horizontally and vertically. Combined with AiRISTA’s low-cost tags, manufacturers can gain a real time view of assets and provide pickers with guided instructions on vertical shelves.

Sofia – AiRISTA’s RTLS Platform

Sofia is AiRISTA’s RTLS solution, delivered from the cloud or on-premises. Connecting to the BLE tags, AoA Gateway and AiRISTA’s many other RTLS components, sofia provides real time insights into industrial asset location data, allowing manufacturers to unlock a comprehensive view of their inventory levels.

Centralize Industrial Asset & Inventory Tracking

When you deploy AiRISTA’s robust industrial RTLS infrastructure, you can automate industrial asset tracking and inventory accounting to streamline the management process, optimize costs and maximize operational efficiency.

Our innovative solutions allow you to carefully balance and manage your inventory levels to avoid overstocking or running out of materials. With this bird’s eye view, your organization gains several key competitive advantages, including:

Unprecedented Visibility

Get real time visibility throughout your entire manufacturing facility and the end-to-end production process. AiRISTA makes it easy to locate critical assets, track their movement and monitor utilization, allowing manufacturers to find the right component at the right time and in the right location.

Improved Asset Utilization

With accurate, up-to-date location data on each asset, manufacturers can quickly and easily identify what’s in use, expired or available. That way, they can make informed decisions to optimize allocation and resource utilization based on factors such as operational needs, time-sensitive materials or proximity to workstations. This efficient allocation makes better use of scarce or expensive assets.

Optimized Inventory Levels

In addition to real time location information, you also get access to historical data on inventory levels and consumption patterns. By analyzing these trends, manufacturers can more accurately forecast future demand, enabling them to align and optimize inventory levels to minimize carrying costs, overstocking or wasted materials due to expiration dates.

RTLS Experts in Industrial RTLS

Discover how manufacturers are currently using AiRISTA RTLS infrastructure to optimize their operations:

Time-Sensitive Inventory Monitoring

Aircraft manufacturers often ship pre-preg rolls (or sheets of material soaked in resin to create carbon fiber) in large, walk-in refrigerators to preserve them. Tracking expiration dates throughout the production process is absolutely essential, as pre-preg rolls could become outdated by the time it’s manufactured into a part. BLE tags allow pickers to select the oldest roll first while ensuring the material remains fresh throughout production.

Get Real Time Visibility With

AiRISTA’s Location Solutions

AiRISTA is the leading provider of RTLS asset tracking solutions, helping manufacturers achieve optimized inventory levels, minimize costs and boost operational efficiency.